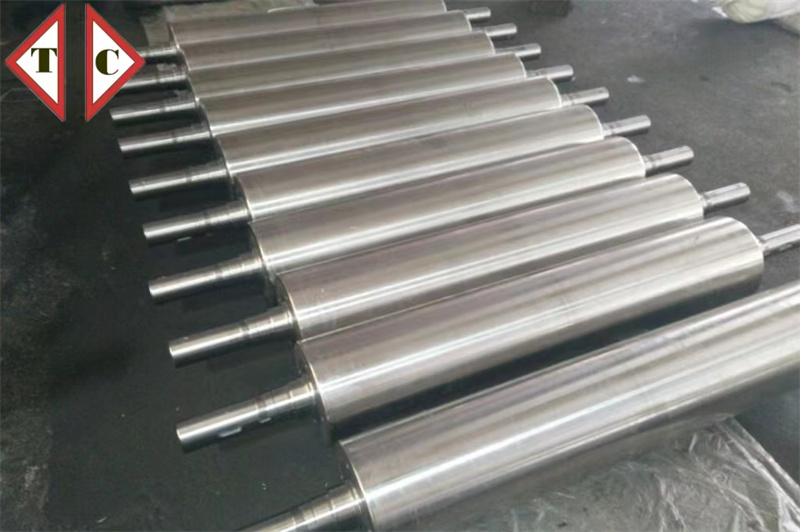

Cov hmoov nplej los yog Grain Mill Roller

Qhov zoo

RAW MATERIAL:

Los ntawm IRON & STEEL GROUP, CO.LTD ntawm cov saum toj kawg nkaus 500 tuam txhab Suav.

ALLOY txheej:

1. Thickness ntawm alloy txheej 25mm + uas yog thicker tshaj feem ntau factories, Yog li yuav ua kom paub tseeb tias cov hardness ntawm cov menyuam zoo dua lwm tus.

2. Tshuab thiab cov khoom siv ntawm alloy .roller lub cev yog ua los ntawm cov nickel zoo -Chromium-Molybdenum alloy los ntawm compound centrifugal casting ntxiv rau hluav taws xob rauv smelting tshuab, xyuas kom peb cov rolls siab hardness, homogenization thiab hnav cov khoom.

TESTING SYSTEM

1. Dynamic tshuav nyiaj li cas kuaj tau ua tiav los lav qhov tseeb ntawm kev khiav haujlwm ruaj khov ntawm yob.

2. Los ntawm kab khoom mus rau cov khoom tiav, ntau tshaj 20 kauj ruam, txhua kauj ruam nrog lub sij hawm ntawm kev ntsuam xyuas nruj kom paub tseeb tias peb cov yob zoo.

Nqe

1. Cov nqi sib tw nrog cov khoom zoo, kev pabcuam ntev ntawm peb cov yob, muaj txiaj ntsig ntau dua rau peb cov neeg siv khoom.

Cov neeg siv khoom hais

Tus nqi pheej yig dua tab sis zoo dua li Qaib Cov Txwv.

Main technical parameters

| Main technical parameters ntawm kev sib tsoo cov menyuam | |||

| Hardness ntawm yob lub cev (HS) | Hardness ntawm xuab zeb yob (HS) | Hardness ntawm lub taub hau axis (HB) | Thickness ntawm alloy txheej (mm) |

| 73 ± 2 | 63 ± 2 | 220-260 : kuv | 20-25 |

Cov duab khoom

Cov ntaub ntawv pob