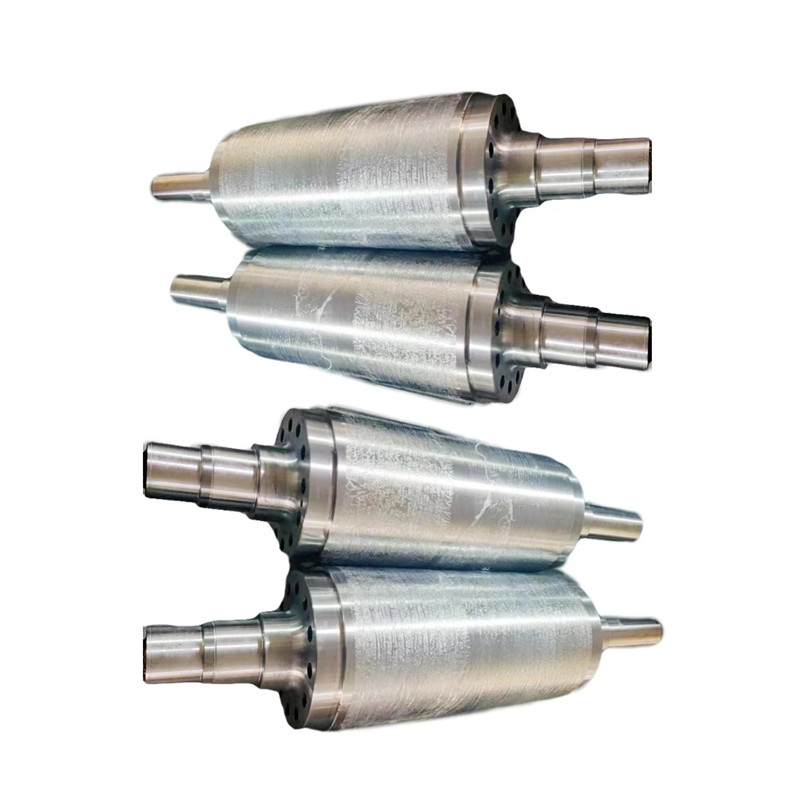

Small size roller for roller mill

Product Description

Small size of roller (170*190, 185*190, 190*250, 185*250, 185*300, 250*400 ,250*600 and so on) is a type of roller used in a roller mill, which is a machine used for grinding or crushing various materials, Roller mills are widely used in various industries, including mining, cement production, pharmaceutical manufacturing, and food processing. They are designed to reduce the particle size of materials through a combination of compression and shearing forces exerted by the rotating rollers. The rollers in a roller mill have specific characteristics that contribute to the milling process. The surface of the rolls can be smooth, corrugated, or grooved, depending on the desired particle size and the stage of the milling process. The rolls can also be adjusted for varying gap sizes between them, allowing for precise control over the degree of grinding. We are ODM for COFCO, Pingle and Kfliangji- three top roller mills manufacturers.

Advantages

RAW MATERIAL

From IRON&STEEL GROUP,CO.LTD among the top 500 enterprises.

ALLOY LAYER:

1. Thickness of alloy layer 15mm+which is thicker than most factories, Thus can make sure of the hardness of roller better than other’s.

2. Technology and material of alloy.roller body is made of high quality nickel –Chromium-

Molybdenum alloy by compound centrifugal casting plus electric furnace smelting technology, make sure our rolls of high hardness, homogenization and wear property

TESTING SYSTEM

1. Dynamic balance tests are done to guarantee the accuracy of stable running of rolls.

2. From row material to finished product, more than 20 steps, each step with times of strict tests to make sure high quality of our rolls.

CUSTOMER CASES

We are ODM for COFCO, Pingle and Kfliangji- three top roller mills manufacturers.

We can also produce all kinds of rolls with special specification according to customers’ requirement.

Product photos

Package lnformation