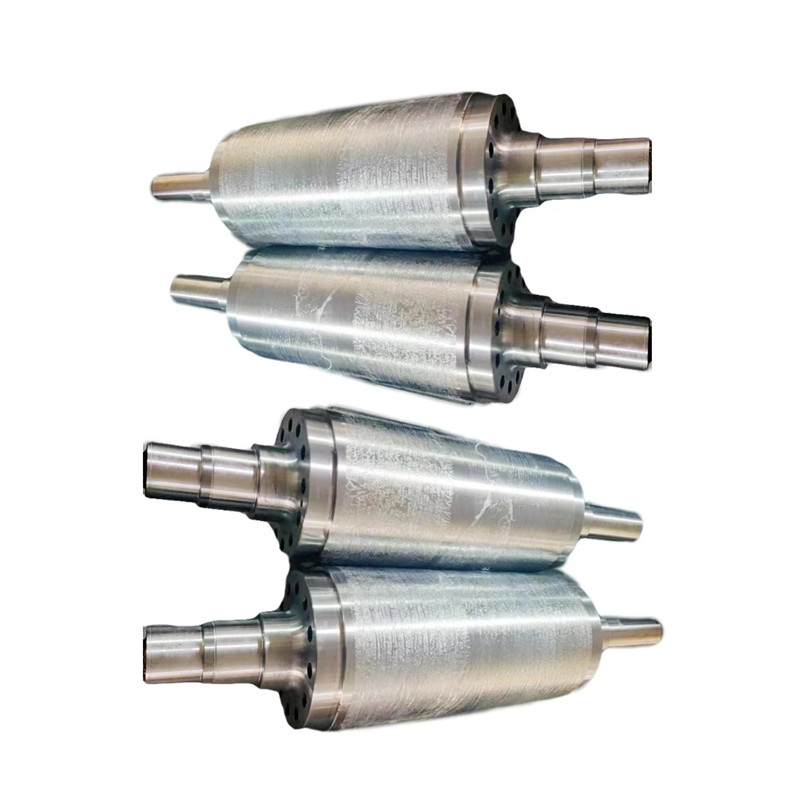

Lirolara tse tharo tse silang Roller

Tlhaloso ea Sehlahisoa

Lirolara tsa k'hamphani ea rona li ka aroloa ka mefuta e 5: lirolara tse tloaelehileng, lirolara tse mahareng, lirolara tse ntle haholo, le letoto la lirolara tse phahameng tsa chromium.

Mefuta eohle ea li-roller e entsoe ka thepa ea boleng bo holimo, e entsoeng ka ho qhibilihisa sebōpi sa motlakase, ho hlahisa li-centrifugal tse kopantsoeng le ho sebetsa hantle.Sebaka sa rolara se thata ka ho hanyetsa ho apara hantle.

Rolara e bohareng ke mofuta o mocha oa thepa e nang le li-alloy content, e hlahisoang ho sebelisoa mekhoa e mecha.E na le litšoaneleho tsa boima bo phahameng ba li-roller, khanyetso e ntle ea ho apara, le bophelo bo bolelele ba ts'ebeletso.Rolara ena e loketse ka ho khetheha bakeng sa ho sila le ho hasanya lihlahisoa tse ntle, tse phahameng tsa viscosity tse nang le viscosity e phahameng.

The ultra-fine roller e entsoe ka lisebelisoa tse ncha, mekhoa le mehaho ea kopano.E na le litšoaneleho tsa boleng bo botle ba thepa, sebopeho sa compact, matla a phahameng le ho hanyetsa ho apara hantle.

Li-roll tse khethehileng tsa alloy content li hlahisoa ho sebelisoa lisebelisoa tse ncha, mekhoa le mehaho ea kopano.E na le litšoaneleho tsa lisebelisoa tse ntle, sebopeho sa lisele tse teteaneng, matla a phahameng, khanyetso e ntle ea ho roala, boima bo phahameng ba holim'a lirolara le phello e ntle ea ho pholisa.Ke rolara e loketseng bakeng sa ho sila makhasi a boleng bo holimo.

Melemo ea lirolara tse tharo tsa leloala

- Abrasion Resistance: Hangata li-roll li entsoe ka li-alloys tse khethehileng tse thata haholo, 'me li hana ho senyeha ha li ntse li sila.Sena se boloka boleng ba grind ka nako.

- Tlhokomelo e tlase: li-roll roller mill rolls li matla ebile li hana ho senyeha, li fana ka bophelo bo bolelele ba ts'ebeletso ntle le tlhokomelo e nyane.

- Matla a Phahameng: Li-alloys li fana ka matla a eketsehileng ha li bapisoa le meqolo e tloaelehileng ea tšepe, e lumellang khatello e eketsehileng pakeng tsa meqolo le ho sila hantle.

- Dimensional Stability: Alloy rolls e hanela ho holofala tlasa meroalo e boima, e boloka likheo tse nepahetseng bakeng sa boholo bo sa fetoheng ba ho sila.

- Customizable: Lirolo tsohle li ka etsoa le ho etsoa ka boholo bo fapaneng le libopeho tse ipapisitseng le ts'ebeliso.

Mekhahlelo ea mantlha ea tekheniki

| Mohlala le Parameter | TR6" | TR9" | TR12" | TR16" | TRL16" |

| Bophara ba Rola(mm) | 150 | 260 | 305 | 405 | 406 |

| Bolelele ba Roller(mm) | 300 | 675 | 760 | 810 | 1000 |

Linepe tsa lihlahisoa

Ho paka