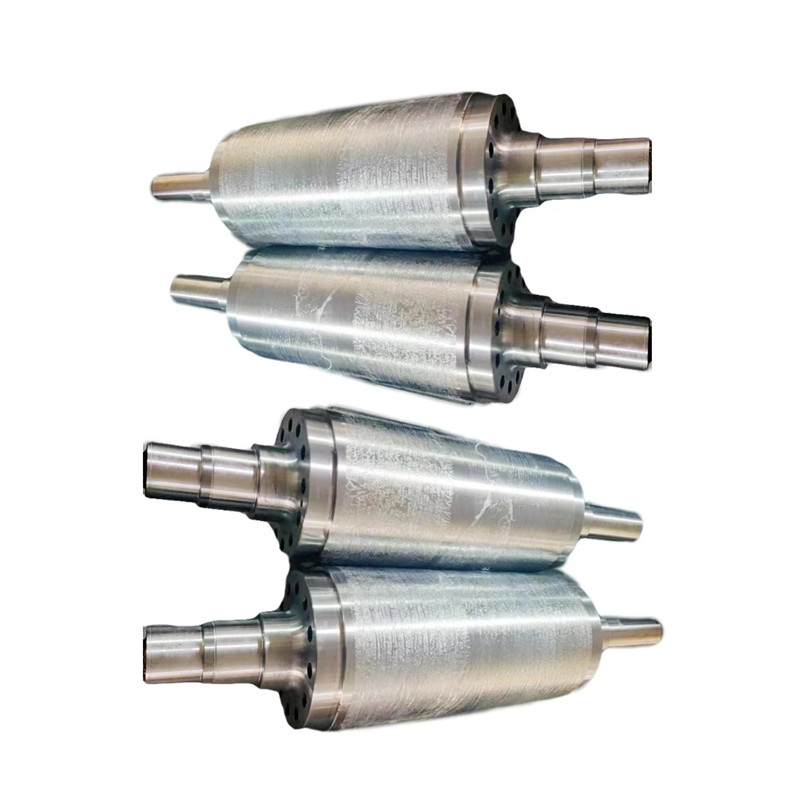

Three Roller Mill Grinding Roller

Product Description

Our company's rollers can be divided into 5 types: ordinary rollers, medium rollers, ultra-fine rollers, and high-chromium roller series.

All kinds of rollers are made of high-quality materials, manufactured by electric furnace smelting, composite centrifugal casting and fine processing. The roller surface is hard with good wear resistance.

The medium roller is a new type of material with medium alloy content, produced using new processes. It has the characteristics of high roller surface hardness, good wear resistance, and long service life. This roller is especially suitable for grinding and dispersing fine, high viscosity products with high viscosity.

The ultra-fine roller is made of new materials, processes and assembly structures. It has the characteristics of good fineness of materials, compact structure, high strength and good wear resistance.

The high alloy content special rollers are produced using new materials, processes and assembly structures. It has the characteristics of fine materials, dense tissue structure, high strength, good wear resistance, high roller surface hardness and good cooling effect. It is an ideal rolling roller for grinding high-quality pulp.

Advantages of three roller mill roller

- Abrasion Resistance: The rolls are typically made of special alloys that have high hardness and resist wear and abrasion during grinding. This maintains grind quality over time.

- Low Maintenance: triple roller mill rolls are robust and resistant to damage, providing long service life with little maintenance.

- Higher Strength: Alloys provide increased strength compared to standard steel rolls, allowing more pressure between rolls and finer grinding.

- Dimensional Stability: Alloy rolls resist deforming under heavy loads, maintaining accurate roller gaps for consistent grind size.

- Customizable: All rolls can be cast and machined to different sizes and shapes based on application.

Main technical parameters

|

Model and Parameter |

TR6" |

TR9" |

TR12" |

TR16" |

TRL16" |

|

Diameter of Roller(mm) |

150 |

260 |

305 |

405 |

406 |

|

Length of Roller(mm) |

300 |

675 |

760 |

810 |

1000 |

Product photos

Packing